Introduction

Dysprosium is one of a group of elements called Rare Earth. Rare earth elements consist of the Lanthanide series of 15 elements plus yttrium and scandium. Yttrium and scandium are included because of their similar chemical behavior. The rare earths are divided into light and heavy based on atomic weight and the unique chemical and magnetic properties of each of these categories. Dysprosium (Figure 1) is considered a heavy rare earth element (HREE).

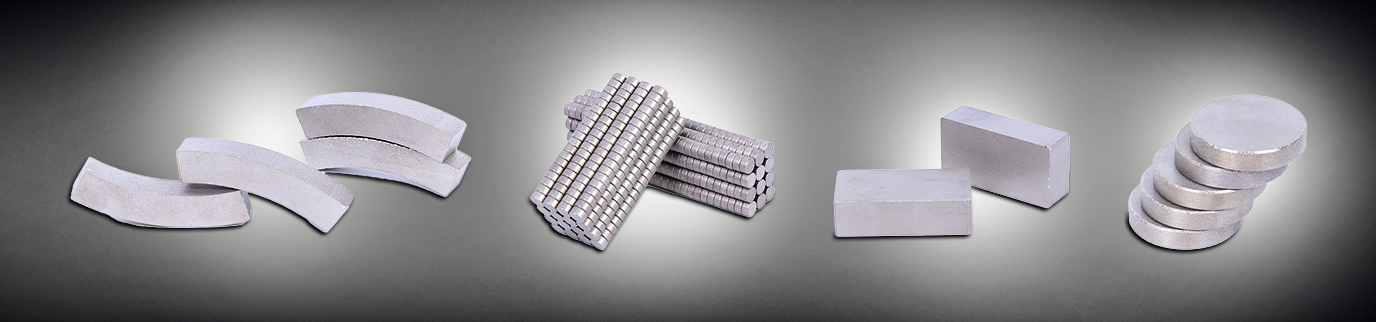

One of the more important uses for dysprosium is in neodymium‐iron‐boron (Neo)permanent magnets to improve the magnets’ resistance to demagnetization, and by extension, their high-temperature performance.

Neo magnets have become essential for a wide range of consumer, transportation, power generation, defense, aerospace, medical

Figure 1: Dysprosium Metal

industrial and other products. Along with terbium (Tb), Dysprosium (Dy) is also used in magnetostrictive devices, but by far the greater usage is in permanent magnets.

The demand for Dy has been outstripping its supply. An effect of this continuing shortage is likely to be a slowing of the commercial rollout or a redesigning of a number of Clean Energy applications, including electric traction drives for vehicles and permanent magnet generators for wind turbines. The shortage and associated high prices are also upsetting the market for commercial and industrial motors and products made using them.

Background

Among the many figures of merit for permanent magnets, two are of great importance regarding the use of Dy. One key characteristic of a permanent magnet is its resistance to demagnetization, which is quantified by the value of Intrinsic Coercivity (HcJ or Hci). Substituting Dy for a portion of the neodymium (Nd) Neo magnets increase the room temperature value of HcJ and also reduces the rate at which it falls with increasing temperature. Thus Dy‐containing Neo magnets have greater resistance to demagnetization over a wider temperature range. The downside of adding Dy is a drop in Residual Induction (Br). The second key characteristic, Energy Product, is proportional to the square of Br.

Therefore, even a small drop in Br results in significantly lower magnet strength.

For applications such as motors and generators, resistance to demagnetization is a critical performance objective and the amount of Dy is dictated, not only by demagnetizing stress but also by the expected maximum temperature of the application. Grades of Neo are most often denoted by a suffix indicating the minimum HcJ ( at 20 °C) and a corresponding recommended maximum operating temperature. These notations are shown in Figure 2. At the top of the chart are some typical applications. Letters inovals along the HcJ curve are suffixes denoting the minimum HcJ of Neo magnets.

For example, “SH” magnets have a minimum HcJ of 20,000 Oe (1590 kA/m). The Dy percentages shown in Figure 2 are typical for materials where all the Dy is added to the starting alloy. Despite recent improvements in alloying and processing, considerable dysprosium is still required for high-temperature applications. Increased demand for higher Dy grades of Neo magnets is one reason why Dy has been in short supply and why prices have stayed relatively higher even after the pricing bubble collapsed. (Efforts to reduce dysprosium will be discussed later) A list of applications and most likely Dy content (traditional alloying) is shown in Table 1. Two green energy applications are Wind Power, in which designs have used 4 to 5% Dy to resist demagnetization at the operating temperature seen in the generators (up to 150 °C), and hybrid or fully electric vehicle traction drives (EVs), in which demagnetization stress can be severe, especially along the leading and trailing edges of the magnets thus requiring Dy as high as 11%.

The recent introduction of dysprosium diffusion ‐ more accurately HRE diffusion since terbium can also be used ‐ in permitting the reduction of HRE content from 4+% Dy for SH grades to ~2% while 8‐11% grades are reduced to 4‐5%.